Whatever You Have Learned, Put It Into Practice

In Building Regulations and within Building Standards (Code for Sustainable Homes or PassivHaus, for example) to meet specific requirements ‘Fabric First’ may be referred to as paying attention to the ‘building envelope’ or the ‘thermal envelope.’

According to Wikipedia, ‘a building envelope is the physical separators between the conditioned and unconditioned environment of a building including the resistance to air, water, heat, light, and noise transfer. The three basic elements of a building envelope are a weather barrier, air barrier, and thermal barrier.’

In simple terms, a building envelope means anything that properly separates the microclimate inside the building from external influences (adverse weather, pollution, smog, etc), including the foundation.

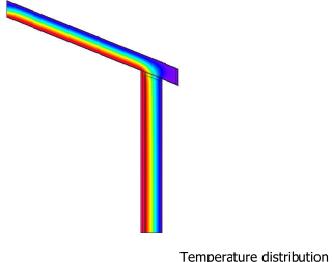

For example, building envelope thermography involves using an infrared camera to view temperature anomalies on the interior and exterior surfaces of the structure. Analysis of infrared images can be useful in identifying moisture issues from water intrusion, or interstitial condensation, as well as heat or cooling loss through the escape of conditioned air, thereby showing the microclimate’s inefficiencies or effectiveness. Therefore there is no excuse not to always utilise this methodology.

However, it is what that building envelope is made of, along with the intermediate floors and foundation, that will be of the upmost importance.

In general, bio-based or recyclates produce a much smaller carbon footprint than steel and performs very well under forces of compression, but steel performs much better when it comes to tension in certain applications.

From an emissions standpoint, if one can provide applicable tension properties out of low carbon materials then one should definitely use those solutions instead of steel.

These solutions also tend to be more cost effective, and easily certifiable. High carbon steel could then be saved for applications where its properties provide maximum benefit.

(Please Note: Off-setting a high-carbon footprint design through documentation only is questionable at best, and does not bring forth the economic and environmental benefits of manufacturing to a low-carbon footprint. Carbon offsetting is a trading mechanism that allows entities such as governments, individuals, or businesses to compensate for (i.e. “offset”) their greenhouse gas emissions by supporting projects that reduce, avoid, or remove emissions elsewhere, and in practice should only be used for critical projects when no other solutions are available.)

WE SUBMIT: High Carbon Material Solutions Do NOT Meet Sustainability Targets

The carbon footprint of materials must be taken into account as well, if a true sustainable measurement is to take place.

Most developers and contractors understand insulation and how it performs as a thermal barrier and ultimately being beneficial for reducing energy consumption which gives them a good energy rating.

Not enough attention is given to the raw or composite materials and solutions that are used to meet energy efficiency targets, which is where the combination either meets or fails on sustainability.

Just adding a low carbon energy solution to a structure may qualify for minimum planning permissions, but it does not add project cost savings nor meet high certification for sustainability for a project viewed in its entirety.

In the ‘Fabric First’ approach the raw materials used for the structure must be understood in detail and how those solutions work with the design and means for preventing water intrusion, controlling air-tightness, ensuring healthy walls/roofs/foundations (the prevention of mould growth or other dangers, for example) and appropriate insulation as this becomes the most important aspect of a build, while internal water vapour and internal odours must be managed by controlled ventilation.

But the ‘Fabric’ of the building is not only the weather barrier, air barrier, and thermal barrier, it includes the foundation, intermediate floors, columns and beams and chosen internal walls and furniture to meet a client’s expectations.

In an appropriate thermal envelope, the ‘Fabric First’ approach allows the building to maintain a controlled micro-climate regardless of the season or temperate climate within the building envelope.

Air-tightness is of the highest importance, as other factors may influence heat or cold performances, and must be detailed and clearly understood around apertures with windows and/or doors, and the air-tightness of this fenestration is where a building is most likely to fail as can be indicated by thermography or through air-tightness of a building.

Moisture and/or condensation must also be addressed, to ensure a healthy indoor environment and to ensure parity of the building envelope.

The building envelope is all of the elements of the outer shell that maintain a dry (humidity-controlled), heated, or cooled indoor environment and facilitate its climate control.

Building envelope design is a specialised area of architectural technology and engineering practice that draws from all areas of material building science and indoor climate control.

Sustainability vs Passive Design

From a builder’s perspective, creating a stable micro-climate within a structure should be the main goal. Due to customer demand, energy efficiency is secondary which most times depend on a large part of a controlled microclimate or expensive add-ons such as renewables (solar, ground source heat pumps/exchangers, capital equipment, etc). Aesthetics/ finishes is the third, and can cost as much as the first two, dependent upon design.

Providing proven and accepted energy efficiencies, PassivHaus principles assists in reducing our dependency on fossil fuels, lowering utility bills, and contribute significantly to a greener, more sustainable environment. PassivHaus is a construction concept, not a brand name. It stands for a building standard that is energy efficient, comfortable and affordable. It provides thermal comfort with very low heating and or cooling demand.

As excellent as these principles are, experience has taught us at Thir13en that life or projects is/are rarely that simple. It all sounds reasonable, logical and straight forward but in practice the issues that address these problems are rarely simple.

Quality control of critical details such as that for fenestration or wall/roof penetrations is imperative, and the use of low carbon materials specified at the design stage is critical to achieve the intent of a properly sustainable design.

PassivHaus principles only look at the energy efficiency of a structure, with specifications (insulation, air-tightness, etc) to achieve that goal.

To truly meet proper sustainability certifications, the materials used to achieve those must be low carbon, where possible, and the solutions to amalgamate the principles with the materials must be agreed, in detail.

Builders, contractors, and even clients have been known to change material specifications even though the specifications are set-in-stone for a variety of reasons, mainly because they naively believe substitution will achieve the same result but this is rarely the case, and can cause a dismal failure in the building envelope and/or the sustainability certification thereof.

This is why following the Integrated Design Process is critical to one’s project, not only to achieve the performance of the thermal envelope while ensuring low-carbon solutions throughout but to achieve the costs vs benefits, and savings, identified by the Integrated Design Process.