Finished to a much higher degree of finish/performance than traditional on-site construction

Working in conjunction with local raw material, component, and appliance suppliers that have adopted our low carbon or circular economy business model, we can achieve a 90% reduced frame construction/erection time, an 80% reduced direct and indirect carbon footprint, and a minimum of 50% less waste.

| Pre-production | off-site production | Logistics | On-site assembly |

|---|---|---|---|

| Estimating, Permitting and 3D Modelling expedites and streamlines accuracy | All controlled components assembled offsite and integrated with each other with precision | Efficiently loading components onto specialised trailers for secure transport and delivery | A seamless, swift, and efficient process under factory trained hands with on-site QC |

| Precision & Consistency | Productivity Increase | Delivery Protection | Safety First, Always |

So, let’s start with the problems. One big contributor to global warming is the ’embodied carbon’ in construction material, encompassing emissions from the fuel used in sourcing, producing and transporting the material and turning it into a building.

According to Archello, the International Energy Agency (IEA) highlights that operating buildings accounts for ”30 percent of global final energy consumption and 26 percent of global energy-related emissions.’ The 26 percent figure equates to a combination of direct emissions (8 percent) from buildings themselves and indirect emissions (18 percent) from producing the electricity and heat [cooling] that buildings use.

Buildings that improve their energy efficiency (and self-sufficiency), particularly those that are energy-positive or energy-neutral, will, in addition to significantly lowering ongoing running costs, improve air quality and comfort levels for their users: in effect, improve the overall health and vitality of people as well as the structure.

A number of factors are related to energy efficiency and the transition to clean energy, including the humidity controls of cooling, heating, and lighting of buildings, and building envelopes. Education is one notable sector investing in sustainable energy as one would expect.

What is not discussed – in detail – is how direct emissions include the carbon footprint of the materials used in structures.

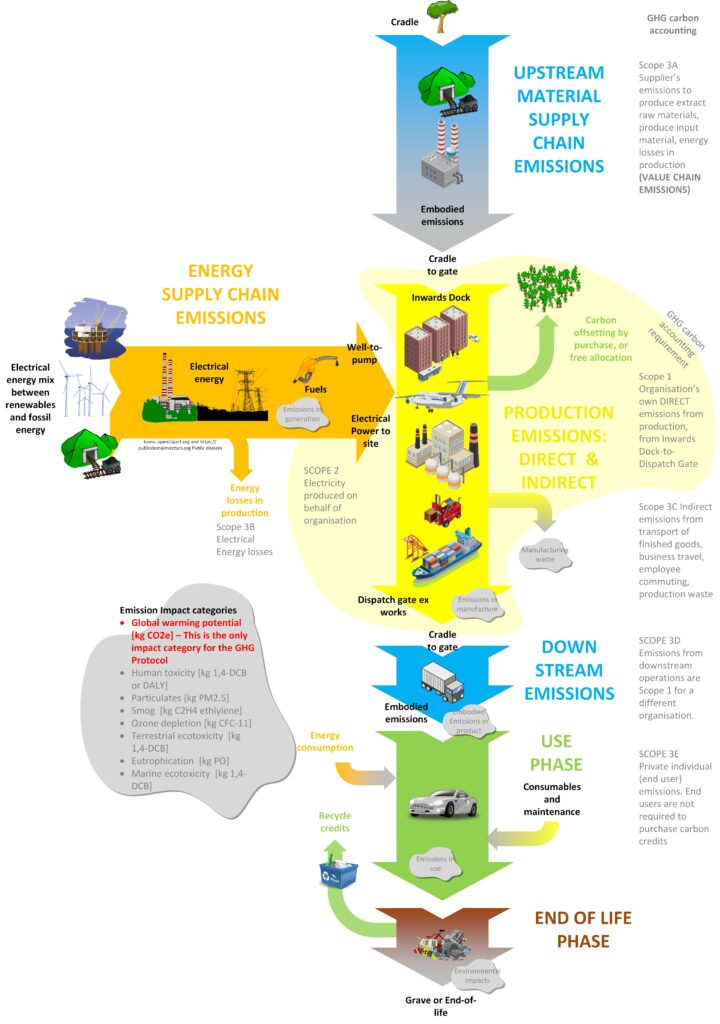

Carbon accounting gets its name from carbon dioxide (CO2), the most common greenhouse gas and the biggest single contributor to man-made global climate change. In most carbon accounting systems, emissions of other GHGs (‘greenhouse gas’) are measured in terms of their carbon dioxide equivalent, or CO2e.

Scope 1 Emissions

These are also known as ‘direct emissions‘, meaning all of the emissions produced as the direct result of a company’s operations. This can include emissions produced by sourcing, manufacturing or chemical processes and electricity produced on-site by water usage and burning fossil fuels.

Scope 2 Emissions

These are also known as ‘indirect emissions‘, resulting from the generation of the electricity, steam, heating, and cooling purchased and consumed by the company in doing its work.

Scope 3 Emissions

Often referred to as ‘supply chain emissions‘, Scope 3 emissions are indirect greenhouse gas emissions that occur as a consequence of the activities of a company, but from sources not owned or controlled by it. In the case of a manufacturer, for example, this can include the emissions produced during the making of the goods or raw materials that it buys from suppliers to make its own product including logistic emissions, the transportation involved in getting its own product to market, consumers’ use of the product once it is in their hands, and even the emissions that employees create in commuting to work.

Most professionals are aware of new regulatory requirements for carbon emissions accounting, but are not necessarily aware of existing low-carbon building and material solutions and how that can affect certain certification processes (BREEAM or LEED as two examples) or one’s potentially profitable bottom line.

KEY TAKEAWAYS

- Carbon accounting is a way for projects, businesses, governments, and even individuals to assess and mitigate their climate impact.

- Carbon accounting methodologies, of which there are several, aim to quantify the emissions produced by an organisation, or a specific project, and is used as a template to mitigate these circumstances.

- Many large companies around the world are required to report their emissions to the government or other regulators, and carbon accounting has become the recognised way to do this.

- Effective, accurate carbon accounting can be a challenge to implement, but it can have many business benefits.

- Low-carbon Solutions allow for lower-cost finance, greater recognition when meeting sustainability targets, and when used as part of a building system, faster construction and quicker cash-flows.

Circular construction is another way to meet low-carbon demands.

This means that as much as possible recycled materials have been used. Demolition materials from other buildings are reused, and the new material used are bio-based or recycled from other applications. Using Building Information Modelling (BIM) in 3-D software can ensure all the materials of the building have been given an identity which is recorded in a digital material passport. This passport ensures the future material’s potential for reuse at the end of a building’s service life. When done correctly with the right low-carbon materials this can result in a BREEAM or LEED – outstanding certification.

BREEAM and LEED are internationally acclaimed third-party certified systems for sustainable built environments that helps improve asset performance with millions of existing buildings across the world registered to work towards BREEAM’s or LEED’s holistic approach to achieve ESG (Environmental, Social and Governance), health, and net zero goals. Both LEED and BREEAM are internationally recognised systems that evaluate buildings based on their environmental impact, resource efficiency, and overall sustainability.

On New Construction, working with BRE (formerly Building and Research Establishment) and BREEAM from the outset significantly lowers sustainable certification costs which can bring in serious sustainability ‘impact’ funds for financing of projects. Low carbon, lower project costs and serious certification instill trust by larger investment funds.

Lightweight yet strong construction systems of prefabricated blocks, floors and panels (strength, compression, bending, shear, heat, fire, thermal and noise insulation produced in one step) for building systems and structural engineering solutions provide ecologically sound alternatives to conventional construction. The new solutions makes use of a technique called topology optimisation, which can produce designs optimised for different characteristics given parameters such as the dimensions of the structure, boundary conditions, and desired performance goals such as the load to be supported and how the structure behaves once erected.

ADVANTAGES

- Preserving the harmony of the environment and nature (to avoid mining basalt, perlite, sand and gravel as aggregates while mostly replacing the raw material with recyclates), leaving ecosystems alone

- Manufacturing and production costs reduced significantly

- Recyclate being used, rather than being ignored by the industry through dumpsites

- Reducing the use of a number of natural or mined raw material deposits, when recyclate is utilised

- Fire-resistant pieces at high temperature can be applied as insulation against heat and as thermal insulation integral to buildings for comfort and energy efficiency

- Approved in-house QC of all approved components by eminent internationally acclaimed third-party certifiers, otherwise brand name and internationally approved certification cannot be used

- All manner of load bearing, and shear-resistant applications can be produced, including insulated load-bearing panels, whole walls, floors, roofs, expanded spans with increased cantilevering potentials, and lightweight construction solutions that provide an environmentally responsible cost-effective solution to an otherwise costly certified construction process

- Lowered costs of construction along with increased speed of construction allows projects to enter into positive cash flows earlier, further reducing overall costs

Lightweight construction can include (dependent upon design):

- 35% lower weight individual finished floors with the same strength as conventional design

- Greater spans (of about 40 times the slab thickness) allows for greater design flexibility, reducing columns accordingly

- Downstand beams are not necessary, producing reduced structure depths, free pipe and services layout and maximum freedom for interior arrangements

- Consequently, reduced concrete and steel usage create a lower carbon footprint

- A dead weight reduction of 50% for the overall building allows for smaller foundations, easier excavations, less cart-aways, and simpler civil engineering

Which leads us back to Fabric First.