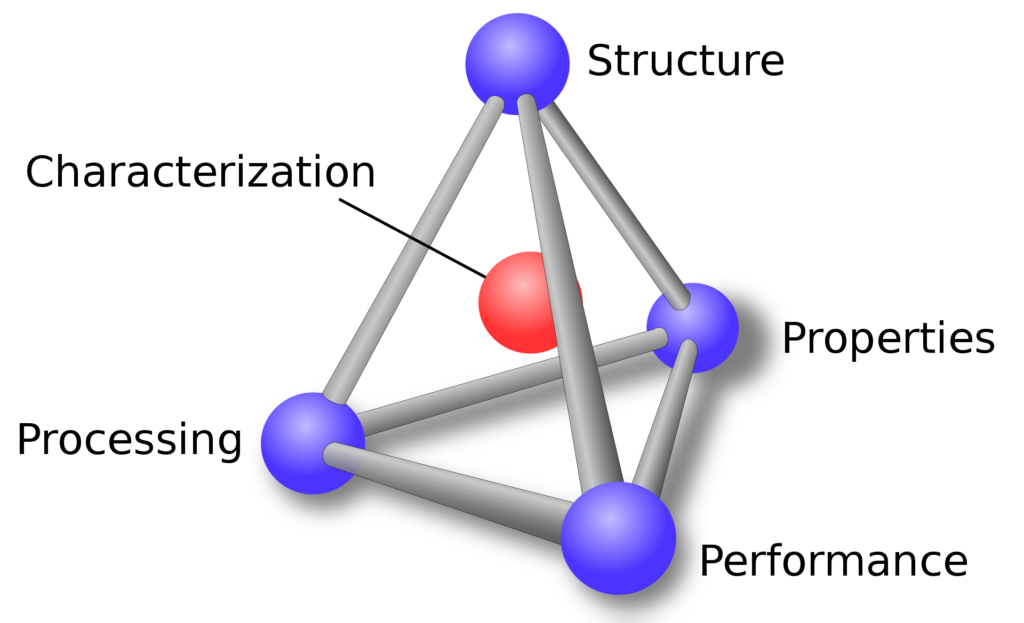

The IDP (Integrated Design Process) challenges us to rethink conventional project design, and construction, with a greater emphasis on up-front understanding of the conceptualisation and goal setting in a sustainable material-science and engineering manner.

The use of metals and alloys, ceramics, polymers, composites and bio-materials all have their own distinct carbon-footprint, which must be taken into account as a distinct part of being sustainable, or not.

Triple Bottom Line thinking maximises and leverages sustainability goals, allowing them to have impact well into and throughout project occupancy with three dimensions of performance: social, environmental and financial.

These dimensions are also commonly called the three Ps: people, planet and profits…

WHY IS INTEGRATED THINKING IMPORTANT?

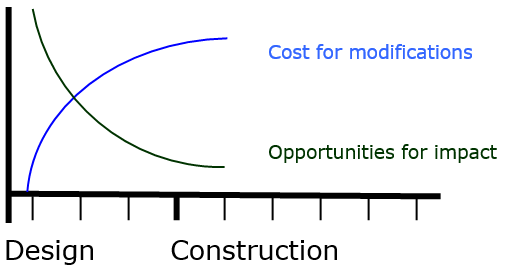

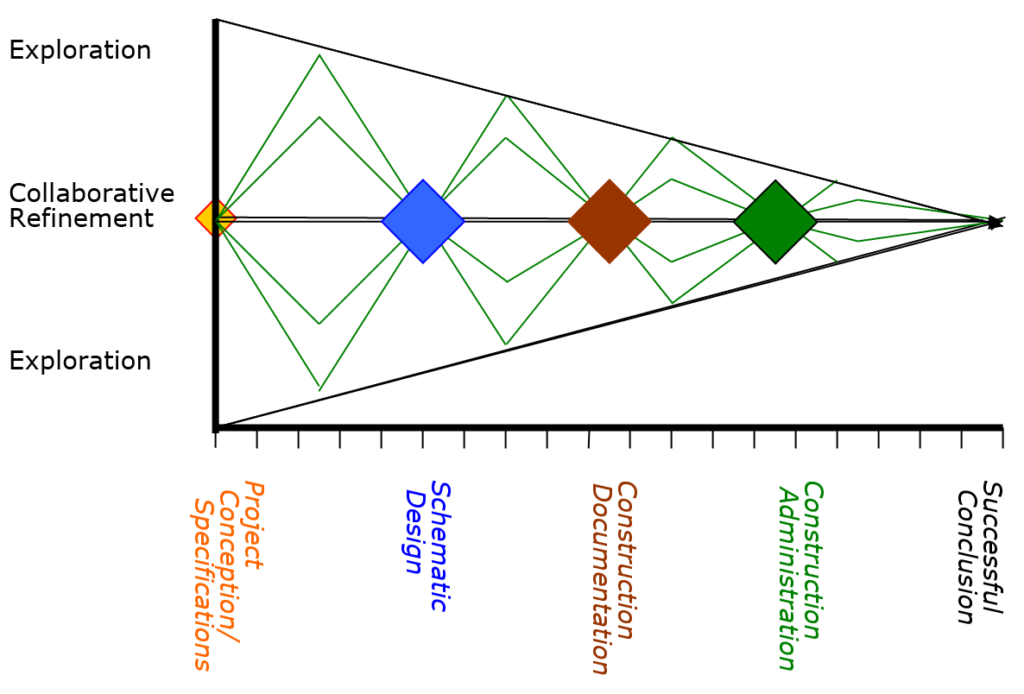

Up-front visualisation and goal setting are critical, for as the project progresses and building materials are chosen opportunities to make effective changes decrease while costs and inconvenience increase. This is not optimal.

WHAT KEY DIFFERENCES ARE THERE BETWEEN CONVENTIONAL AND INTEGRATED DESIGN PROCESSES?

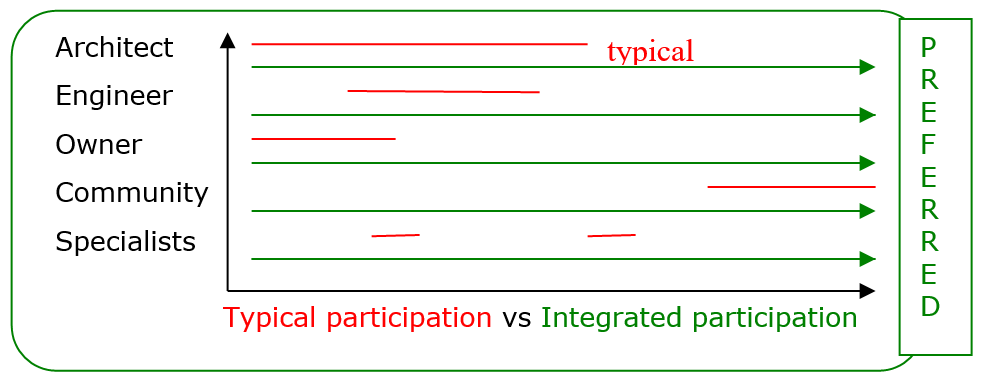

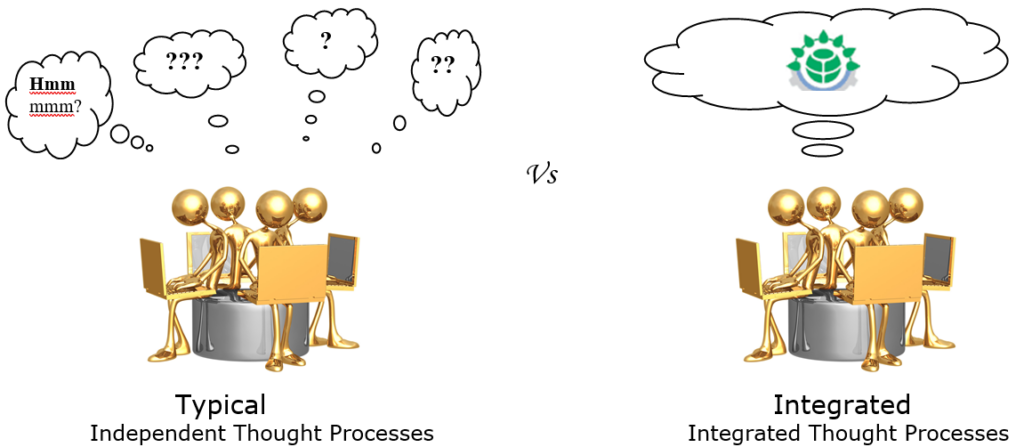

The conventional process engages design and construction professionals on a need-to-know basis, which is not good science. The Integrated Design Process (IDP) works to identify and engage stakeholders early and throughout, in order to establish and work correctly toward project goals in unison on a holistic basis.

Project-Based Inquiry: Can it get us to where we need to be in regards to complex thinking? Multiple variables can make this a complex approach, potentially overlooking finer details while a broad perspective may make scientific testing and verification difficult.

An Integrated Design Process (IDP) brings all stakeholders to the table, using constructive questioning throughout, double-checking matters such as low-carbon solutions for every step of a structural puzzle, allowing designers and engineers different science-based proven options to opt for to complete an overall approved design and construction platform.

Individuals may be exceptionally good at what they do by themselves, while experts in varied fields working together in an integrated 3-D environment ensure fail-safe assurances of meeting project requirements and achieving third-party certification.

Just as one wants a doctor to look at one’s health from a holistic perspective that doctor may refer to specialists for specific advice to ensure completeness, the same applies to the functioning of one’s home, or any building for that matter.

HOW DOES IT WORK?

The Integrated Design Chart process allows for ambitious goal setting within a framework that establishes discipline and accountability through multiple feedback loops.

- Owners Project Requirements (has decarbonisation been taken into account?)

- Goal Setting Charts and Outline Planning (certification criteria)

- Stakeholder Surveys and Mapping/Fact Finding

- Establishment of Key Performance Indicators (low-carbon, sustainability, structural engineering)

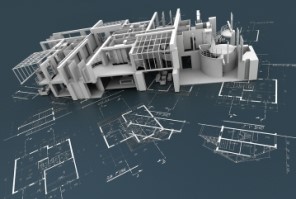

- 3D Design/BIM showing applicable

- Specifications which leads to

- Pre-certification, Documentation and Detailed Planning

- Contract negotiations and

- Construction Phase

- Project Management Specialist ensuring 1 through 13

- Commissioning, Structural and Specification Sign-off

- Final Certification and

- Documentation

Please NOTE: Just because one is building a home, for example, instead of a large commercial building this should not mean that the integrated design process should be scoffed at, or ignored. Too many times we see local builders and house developers opt to move forward on a design that has basically just got through Planning, whereupon problems arise on a constant basis. It can be as simple as not meeting the thermal efficiencies required of the building envelope along with air-tightness and proper ventilation, to more complicated matters such that services, waste pipes, duct-work and power supply ‘crash’ in competition for space as project managers ‘just get on with it’ and are used to solving these problems on site. The sustainability of materials are rarely considered, and many times energy efficient solutions are basic add-ons rather than being designed in from the outset.

This is fine when budgets allow for over-runs and people’s track record tend to instill one with confidence, but in this day and age of seriously increased costs of building materials, skilled and semi-skilled labour shortages, more restrictive building controls and stricter building regulations, there truly does not exist any excuse for not using integrated design, with 3-D models and/or BIM (Business Information Modeling) as the underlying design principle that everyone can work around. This is certainly a must now for larger, more complex buildings.

Designing in 3-D is no longer a mystery… It is considered part and parcel of most successful design and construction firms throughout the world, with most smaller design practices having adopted same years ago. Particular design programmes have been created specifically for the construction of buildings and with the integrated design process it is no longer difficult to ensure the running of services, beams, ducts etc. ensuring all can all be placed correctly and work in unison to the intended design using tested and certified low-carbon material compositions.

The future of Certified Building Systems and the Integrated Design Process lies not only in the ability to adopt the use of certified building systems and/or solutions with the ‘whole building design process’ in mind using, preserving and respecting the natural biospheres’ earth systems of recycling air, waste and water while being fully energy efficient.

It requires an understanding of chemical and structural engineering combined with all the other disciplines to ensure that low-carbon solutions are fit for purpose, and can be certified through sustainability stratagems.

Certified Building Systems can tend to offer unequalled cost efficiencies over conventional construction, saving time, labour, energy and material costs to meet sustainability targets, and an integrated design process team will make the most of that to satisfy a client’s expectations in the design as well as with the finished product.

When project clients understand this, we can then advise on the appropriate technology to be incorporated into the project, from manufacturing facilities to third-party suppliers of solutions that allows the project to achieve its goals and ambitions.